What is Silicosis and What Causes Silicosis?

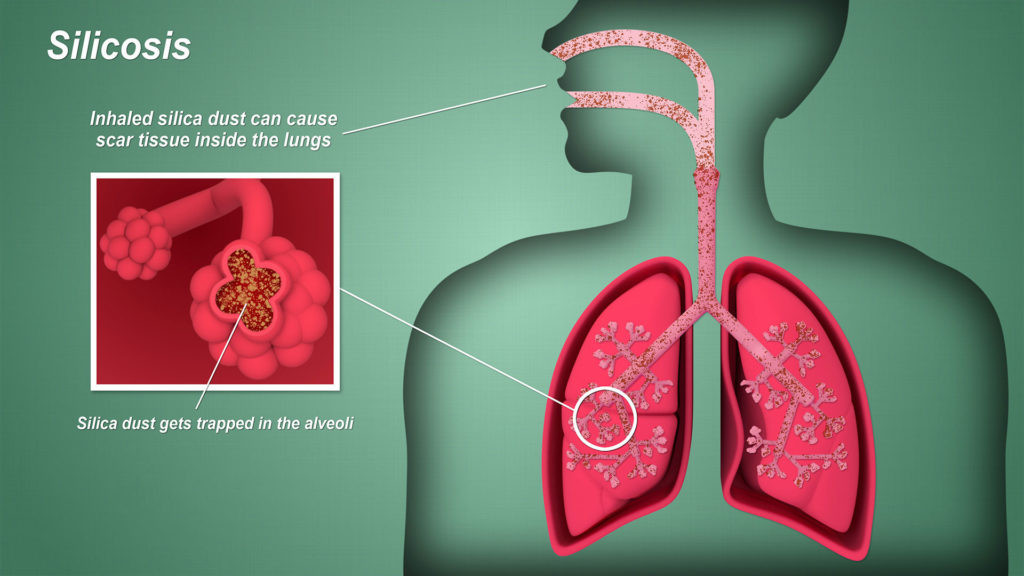

People who work with certain materials in the construction industry may inhale silica-containing fine dust. Once inside the lungs, dust particles can cause scarring. Silicosis is the medical term for this scarring.

Silicosis is a long-term lung disease caused by inhaling dangerous levels of silica dust over a long period of time and if often linked to those working in the construction industry.

Silicosis can cause breathing difficulties, a serious lung condition known as Progressive Massive Fibrosis (PMF), and lung cancer. Silicosis has no known cure and can be fatal, which makes it important to have dust monitoring and dust control measures in place at all job sites.

Types of silicosis

All types of silicosis will affect your health dramatically. The main difference between the three types of Silicosis is how long it takes for silicosis symptoms and problems to develop.

Chronic silicosis — exposure to silica dust for more than 10 years.

Accelerated silicosis — exposure to silica dust for 3 to 10 years.

Acute silicosis — develops within weeks or months of exposure to silica dust.

What are the symptoms of silicosis?

- Shortness of breath

- Cough

- Feeling of a tight chest

- Wheezing blocked or runny nose

Shortness of breath after exercise, chest pain, a harsh, dry cough, and tiredness are the most common symptoms of silicosis. However, there may be no symptoms in the early stages of silicosis, which is what makes this disease so dangerous.

As the condition worsens, the symptoms become more severe. Simple activities like walking or climbing stairs may become difficult at some point. You may also have difficulty sleeping and eating properly.

Silicosis increases the risk of developing other serious conditions such as tuberculosis (TB), chest infections, emphysema, kidney damage, and lung cancer.

If you develop silicosis symptoms, contact your doctor immediately if you work or have worked with products that generate silica dust.

Who is at risk of developing silicosis?

If you work with quartz, sand, stone, soil, granite, brick, cement, grout, mortar, bitumen, or engineered stone products, you are at risk of silicosis.

You are at risk of developing silicosis if your job requires you to:

- Creating and installing engineered or manufactured stone countertops

- Plant excavation, earth moving, and drilling operations

- Machine operations for clay and stone processing

- Mining, quarrying, and mineral ore processing processes paving and surfacing

- Tunnelling construction labouring brick, concrete, or stone cutting, particularly using dry methods

- Blasting with an abrasive (blasting agent must not contain greater than 1 per cent of crystalline silica)

- Angle grinding in foundries, jack hammering and chiselling in concrete or masonry, hydraulic fracturing in gas and oil wells, pottery making

How Can I Protect Myself?

Controlling employee exposure to risks at work is essential for worker safety. The six tiers of activities in the Hierarchy of Controls to lessen or eliminate dangers are based on efficacy. Elimination is at the top of the list for protection and reliability, and the lowest and least dependable levels are listed in reverse order (Personal Protective Equipment – PPE). The application of this hierarchy can lessen worker exposure to silica dust as well as the dangers of silicosis, disease, and damage. You must follow the hierarchy as a worker.

According to Work Health and Safety (WHS) Regulations, a Person Conducting a Business or Undertaking (PCBU), such as an employer or small business owner, has certain obligations to control the risks to the health and safety of employees.

Elimination

- Sometimes unfeasible, such as presence of silica in the mining, construction, tunnelling, and demolition environment.

Substitution

- Substitute silica-containing materials with non-silica-containing materials

- Use silica-containing materials that do not need to be cut, ground or polished

- Design buildings with pre-built recesses so there is no/less need to cut or drill masonry

- Use materials for production of benchtops with no or less silica

Isolation

- Enclosed room with restricted access for dust-generating activities (fitted with appropriate ventilation systems)

- Enclosures around transfer points (i.e. crushers, conveyor systems)

- Enclosures around drop chutes and waste bins

- Enclosed cabins fitted with filtration systems for heavy plant and machinery operators

- Physical barriers between different workers

- Shielding around automated processes

- Designating separate area for changing and amenities

Engineering Controls

- Automated cutting, grinding and drilling

- Wet-cutting methods

- Dust suppression systems

- Ventilation and dust capture systems

- Local exhaust ventilation such as axial and centrifugal systems to remove silica dust close to the source before it reaches the breathing zone of a worker

- On-tool dust extraction and filtration

- H-class industrial vacuum cleaners for cleaning

Administrative Controls

- Obtaining the Safety Data Sheet for all materials used and informing and consulting with workers of the hazards and necessary controls to be applied

- Written rules and policies for handling silica-containing materials and disposing of waste

- Planning to minimise the number of cuts performed by workers that are necessary

- Shift rotation policies to avoid extended exposure

- Restricted area access policies

- Policies for wetting down dusty areas

- Regular housekeeping, including a prohibition of dry sweeping or dry cleaning methods

- Inspection and testing programs (e.g. regular inspection and testing of ventilation systems)

- Training in the hazards and risks of silica dust, the health effects of exposure, the control measures needed to eliminate or otherwise minimise exposure, methods applied to monitor the effectiveness of control measures

- Supervision of workers

- Frequent cleaning and changing of uniforms to avoid contaminating non-work areas, providing washing and showering facilities

- Respiratory protection programs which include respiratory fit-testing for close-face fitting respiratory protection

- Clean shaven policies mandated for workers who are required to wear close-face fitting respiratory protection

- Exposure monitoring program

- Health monitoring program

Personal Protective Equipment

- Includes use of a well-fitting, appropriately selected respirator

- Close face-fitting respiratory protection with an effective face seal, correctly fitted and fit-tested

Control Hire

Control Hire are experts in construction site equipment needed for dust control, noise control, ventilation control and fume control. Ensure that your workers are protected each day. Click here for more information or a free consultation.